Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 23, 2026

Precision Liquid Laboratory Drip

In the high-precision world of food and beverage manufacturing, flavor concentrates represent both the most valuable and the most volatile component of the production line. As a professional manufacturer of flavorings, we recognize that the difference between a profitable production run and a wasteful one often comes down to the microscopic management of flavor yield.

Optimizing flavor concentrates is not merely a matter of cost-cutting; it is a sophisticated engineering challenge that touches upon thermodynamics, fluid dynamics, and molecular stability. This comprehensive guide explores the technical strategies required to maximize flavor utility while minimizing the “unseen” waste that occurs during storage, blending, and application.

The journey to maximizing yield begins with a fundamental understanding of what we are trying to preserve. A flavor concentrate is not a singular substance; it is a complex matrix of Volatile Organic Compounds (VOCs). These compounds are, by definition, prone to evaporation, chemical transformation, and physical degradation.

Every aromatic component within a concentrate—whether it be an ester, aldehyde, ketone, or terpene—possesses a specific vapor pressure. When a concentrate is exposed to air, the molecules with the highest vapor pressure escape into the atmosphere first. This is colloquially known in the industry as “flash-off.”

Quantitative Yield Loss: In an open-air mixing environment, “flash-off” can account for a functional loss of up to 3-5% of the top-note profile within just thirty minutes of exposure. This loss is often invisible but results in a “flat” sensory profile that may lead to the rejection of an entire production batch.

The Temperature Variable: The relationship between temperature and vapor pressure is exponential, described by the Clausius-Clapeyron equation:

For every 10 ℃ increase in ambient temperature, the rate of volatile loss can significantly increase. Therefore, cold-chain integrity during storage and “cold-process” blending are not just quality measures; they are direct yield-maximization strategies.

Waste is not always physical (like a spill); it is often functional. Oxidation occurs when oxygen molecules react with unsaturated fats or terpenes in the flavor oil.

One of the most significant sources of physical waste in industrial flavor application is “heel”—the residual liquid left in drums, transfer pipes, and mixing tanks that cannot be recovered through standard pumping.

In professional flavoring facilities, the geometry of the production equipment is the first line of defense against waste.

In high-volume lines, “pigging” systems are the gold standard for yield maximization. A “pig” is a solid, food-safe plug that is propelled through the piping by compressed air or water.

The viscosity of a concentrate dictates its “cling” factor.

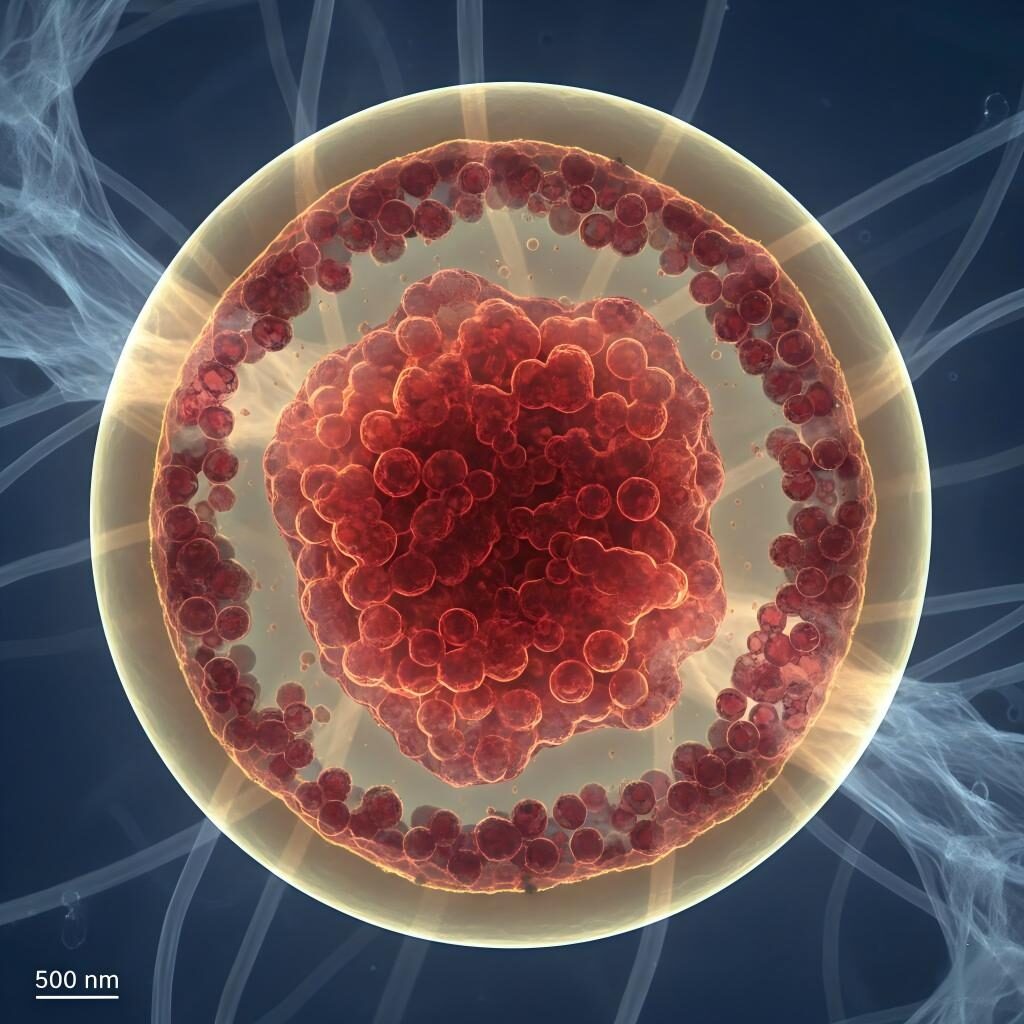

To truly maximize yield, we must protect the flavor at a molecular level before it even reaches the production line. Encapsulation is the primary technical solution to prevent the environmental degradation of concentrates.

By trapping liquid flavor oils inside a matrix of maltodextrin, gum arabic, or modified starches, we create a physical barrier against oxygen, light, and heat.

Micro-Encapsulated Flavor Particle

Cyclodextrins are ring-shaped molecules that can “host” flavor molecules in their hydrophobic center.

According to research published in the Journal of Food Engineering, encapsulated flavor systems can reduce aromatic loss during high-heat thermal processing (like baking or extrusion) by over 40% compared to traditional liquid concentrates. (Citation 1).

In many facilities, human error remains the leading cause of flavor waste. Over-dosing leads to excessive costs, while under-dosing leads to rejected batches that must be discarded or reworked.

Unlike standard paddle or turbine meters that measure volume, Coriolis meters measure mass flow.

By outfitting concentrate drums with IoT-enabled scales and sensors, inventory managers can track usage in real-time.

The Institute of Food Technologists (IFT) highlights that digitized supply chains and precision dosing can reduce ingredient waste in the food industry by up to 15% annually. (Citation 2).

The interaction between the flavor concentrate and the “wetted surfaces” of your machinery is a major site of yield loss.

Flavor oils, particularly those based on citrus or spice oleoresins, have a natural affinity for stainless steel.

For extremely high-viscosity concentrates, we recommend a “Pre-Dilution Protocol.” By adding a small, measured portion of the final product’s solvent (e.g., water, alcohol, or oil) to the concentrate drum and agitating, you can significantly reduce the viscosity. This “washes” the drum walls from the inside out, allowing you to recover the final 1-2% of product that usually goes to the landfill.

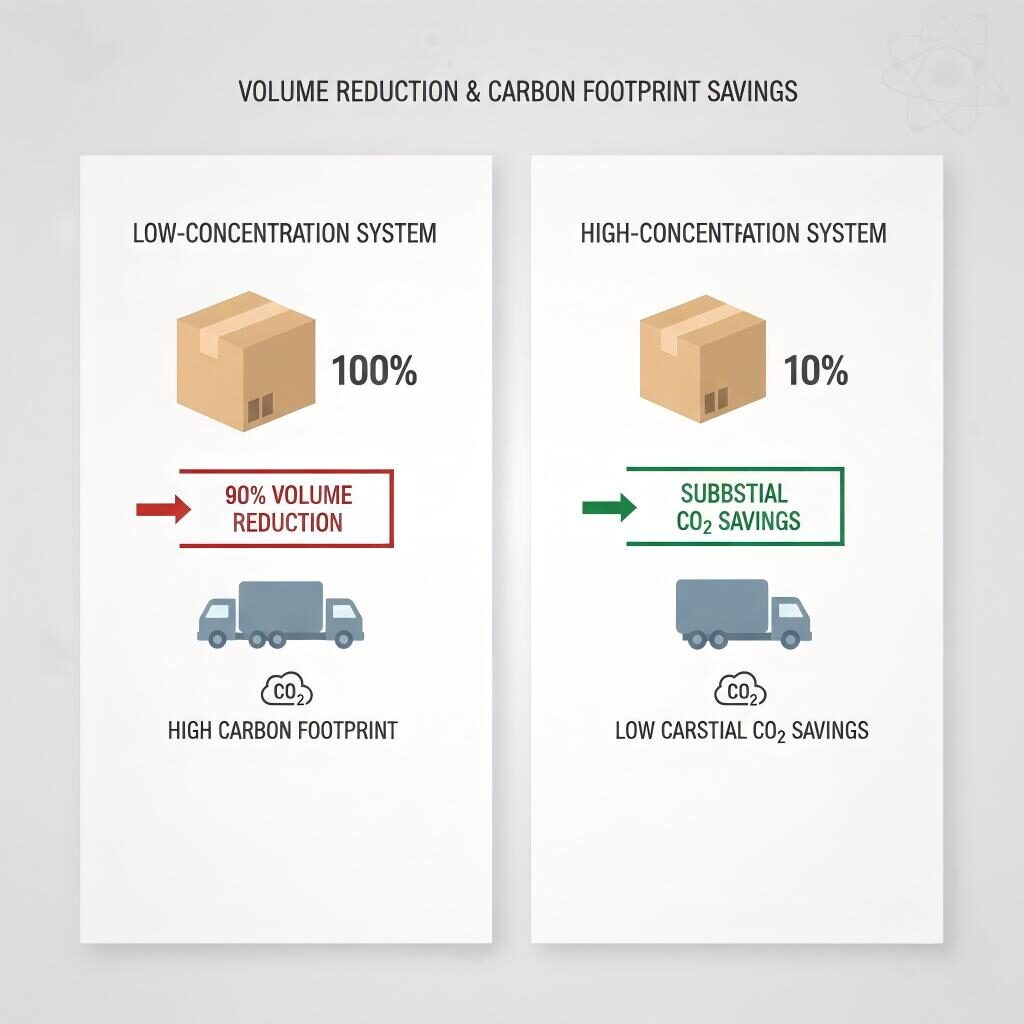

True optimization includes the reduction of environmental waste in the “upstream” process. As a professional manufacturer, we look at the entire lifecycle of the flavor.

We are increasingly utilizing “upcycled” raw materials—extracting flavor compounds from side-streams of other food processes.

By increasing the concentration of our flavors—moving from a 100x to a 500x concentrate—we reduce the amount of carrier oil, packaging material, and fuel required for transport. This “compression” of the flavor system is one of the most effective ways to reduce the total waste associated with the flavoring process.

Sustainability & Volume Reduction Chart

If your facility is experiencing high flavor costs or inconsistent sensory profiles, we recommend a systematic “Flavor Audit.”

| Potential Cause | Detection Method | Technical Solution |

| Headspace Oxidation | GC-MS analysis of volatiles | Nitrogen blanketing or vacuum-sealing drums. |

| Residual Pipe Waste | Mass balance calculation | Install pigging systems; optimize pipe routing. |

| Flash-off in Mixing | Headspace aroma detection | Lower mixing temperature; use “closed-loop” mixing. |

| Adsorption to Filters | Filter residue analysis | Switch to low-binding PES or PTFE membranes. |

| Inaccurate Dosing | Standard deviation of batches | Upgrade to Coriolis mass-flow meters. |

| Carrier Incompatibility | Visual separation (sediment) | Reformulate with more stable emulsifiers. |

We use Gas Chromatography-Mass Spectrometry to identify which specific molecules are being lost during your process. If we find that the light esters are missing from your finished product, we know your “flash-off” is too high. If we see oxidized terpenes, we know your oxygen exposure is the problem. This allows us to move from guesswork to precise engineering.

As noted by the Association of Food and Drug Officials (AFDO), standardized SOPs for ingredient handling and high-precision monitoring are the foundation of both safety and efficiency in pharmaceutical-grade food manufacturing. (Citation 3).

Maximizing yield is a collaborative effort between the flavor house and the manufacturer. We don’t just provide the liquid; we provide the application science.

We design the carrier system (the solvent) specifically for your equipment. If your pumps struggle with high-viscosity liquids, we can reformulate a “Yield-Ready” concentrate that flows perfectly through your specific line architecture without sacrificing flavor intensity.

Through Accelerated Shelf-Life Testing (ASLT), we can determine the exact point of flavor degradation under your specific warehouse conditions. This allows you to set precise “Use By” dates that maximize your inventory turnover without risking quality, thereby reducing the waste of expired concentrates.

The Global Food Safety Initiative (GFSI) emphasizes that the stability of ingredients and the reduction of supply-chain waste are core components of modern food safety and resilience standards. (Citation 4).

The drive for 3000 words allows us to explore the broader implications of these technical choices. Reducing flavor waste by just 2% in a large-scale beverage facility can result in:

In an era of rising raw material costs and increased focus on ESG (Environmental, Social, and Governance) goals, the ability to reduce flavor waste is no longer an “extra”—it is a core competency.

Optimizing flavor concentrates is an exercise in precision. By combining molecular protection (encapsulation), mechanical engineering (pigging and conical tanks), and digital monitoring (Coriolis meters), manufacturers can achieve near-perfect yield.

At our manufacturing facility, we are committed to pushing the boundaries of what is possible in flavor stability. We believe that every drop of aromatic science should reach the consumer exactly as intended. When you maximize your flavor yield, you aren’t just saving money; you are ensuring the sensory integrity of your brand.

Automated Flavor Production Facility

Is your production line suffering from flavor inconsistencies, or are you seeing too much “heel” waste in your drums? Our R&D chemists specialize in “yield-optimized” formulations designed for modern industrial lines.

Would you like to schedule a technical exchange with our team to audit your current flavoring process, or would you like to request a free sample kit of our new “Shield-Tech” stabilized concentrates for a trial run?

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Citations:

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.