Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 26, 2026

Precision Flavor Crafting Lab

In the modern food and beverage landscape, the pressure to maintain healthy margins is relentless. Procurement departments are often tasked with a singular, high-pressure goal: cost reduction. In this race to the bottom, the flavor—often the most critical component of a product’s identity—is frequently treated as a mere commodity. However, treating flavor as a line item to be minimized rather than a strategic asset to be optimized is a fundamental misunderstanding of food science and consumer psychology.

As a professional manufacturer of food and beverage flavors, we have observed a recurring pattern: companies that prioritize “price per kilogram” over “value per application” eventually face a “complexity tax.” This tax manifests as lost consumer loyalty, increased dosage requirements, manufacturing inefficiencies, and regulatory hurdles. This comprehensive technical analysis explores why the cheapest flavor options often lead to the highest long-term costs and why investing in premium flavor systems is the only sustainable path for brand growth.

To understand the true value of a flavor, one must look beyond the invoice price and delve into the molecular composition of the ingredient. A “cheap” flavor is rarely a triumph of manufacturing efficiency; more often, it is a result of dilution or the use of lower-purity precursors.

In the flavor industry, the “sticker price” is a deceptive metric. The only figure that truly impacts your Bottom Line is the Cost in Use (CIU).

Lower-cost flavors are frequently diluted with high ratios of solvents—typically Propylene Glycol (PG), Vegetable Glycerin (VG), or Triacetin. While these solvents are necessary carriers, an excess of them means you are paying for “filler.”

Consider the following mathematical comparison:

In this scenario, the “expensive” flavor is actually 28% cheaper to use. Furthermore, using less flavor means you are introducing fewer secondary carriers into your product, which can affect the viscosity, clarity, and label transparency of the final beverage.

The synthesis of aromatic chemicals is a precise science. A single molecule, such as Vanillin or Ethyl Butyrate, can be produced via various pathways. Budget manufacturers often use technical-grade chemicals that contain trace impurities—isomers or residual solvents—from the manufacturing process.

These impurities may not be toxic, but they are sensorially active. Even at parts-per-billion levels, these “chemical artifacts” contribute to what tasters call a “plastic,” “metallic,” or “solvent-like” aftertaste. High-quality flavor houses utilize USP-grade or higher purity molecules, ensuring that the profile remains “clean” from the first sip to the last.

A premium strawberry flavor is not just one molecule; it is a symphony of over 30 to 50 distinct components, including esters for fruitiness, lactones for creaminess, and green notes for “fresh-picked” authenticity. A cheap alternative might rely on 3 or 4 high-impact molecules. While the budget version might pass a “quick sniff” test, it lacks the “roundness” and “evolution” on the palate that consumers associate with premium brands.

Flavor does not exist in a vacuum. Once introduced into a food matrix—whether it’s a high-protein yogurt, a high-fat bakery item, or an acidic carbonated drink—the flavor begins to interact with its surroundings.

“Flavor scalping” is a phenomenon where the packaging material (such as Low-Density Polyethylene or certain resins) selectively absorbs specific flavor molecules. This often leaves the product tasting unbalanced—for example, losing its top-note citrus zing while retaining a heavy, sugary base.

Quality flavor manufacturers perform compatibility testing. We engineer flavors with specific partition coefficients (logP values) to ensure they stay in the food or beverage and don’t migrate into the plastic lining of the bottle or the foil of a pouch.

Many food processes involve extreme heat: UHT pasteurization, HTST (High-Temperature Short-Time) processing, extrusion, or industrial baking.

Premium flavor systems often employ Advanced Encapsulation Technology. By trapping volatile oils inside a protective matrix (such as modified food starch or maltodextrin), the flavor is protected from heat during processing and is only released when the consumer eats the product (via mechanical shear or saliva dissolution).

In products containing fats and oils (like snacks or plant-based milks), lipid oxidation is a constant threat. While antioxidants help, a high-quality flavor system is designed to be “oxidatively stable.” Budget flavors often contain carriers that can actually accelerate the oxidation of the base, leading to a shortened shelf life and a “stale” consumer experience.

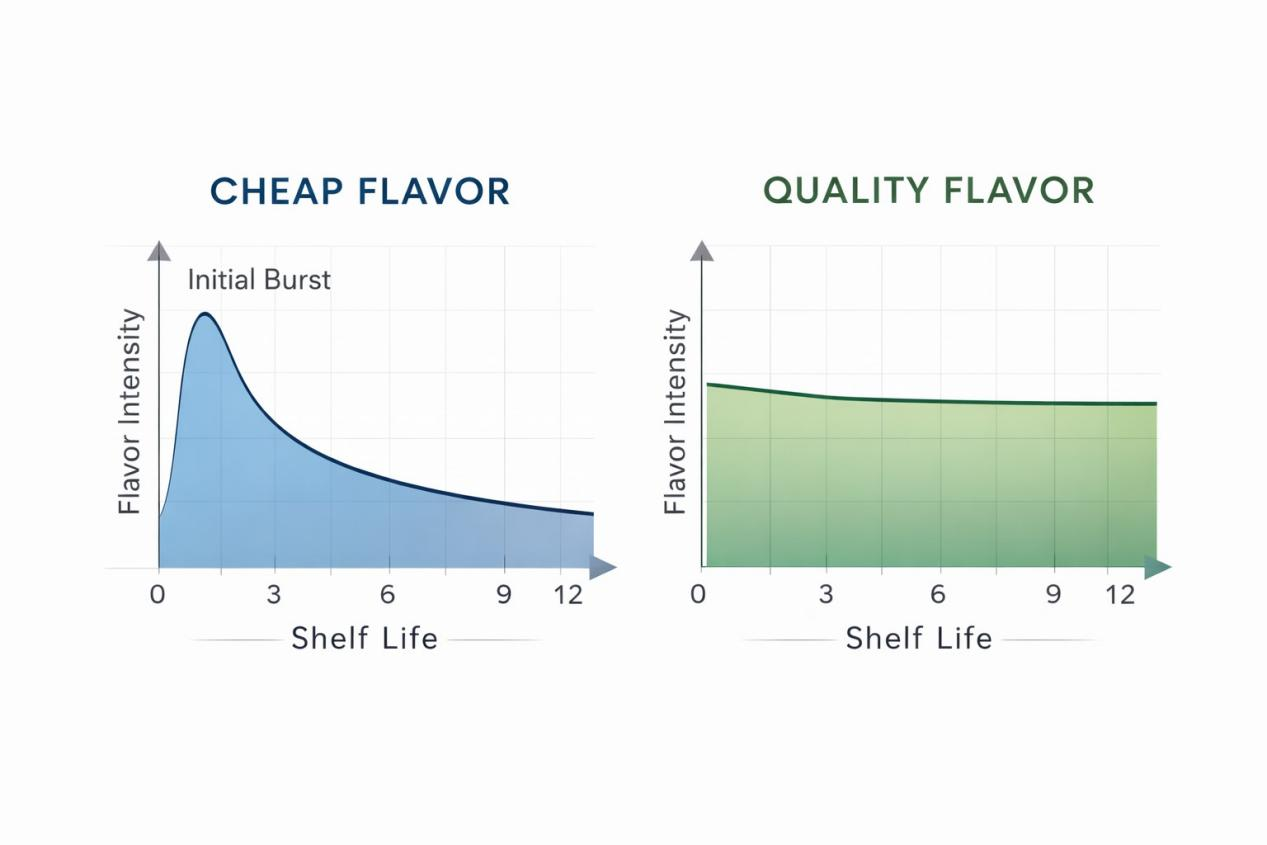

Flavor Stability Comparison Chart

The global food industry is governed by a patchwork of strict regulations. Using a flavor from a “budget-first” supplier can expose your company to immense legal and financial risk.

When you purchase a flavor, you are also purchasing the documentation that proves its safety. A premium manufacturer provides a full suite of paperwork:

Budget suppliers often struggle to provide detailed “sub-ingredient” breakdowns. If a regulatory body like the FDA or EFSA requests information on a specific trace component, a lack of transparency from your supplier can stall your production or lead to a mandatory market withdrawal.

In the United States, flavor ingredients must be “Generally Recognized as Safe” (GRAS). The Flavor and Extract Manufacturers Association (FEMA) maintains a rigorous list of approved substances. According to FEMA, using non-approved substances—which sometimes find their way into “grey market” or ultra-cheap imported flavors—can lead to immediate product seizures. Premium manufacturers ensure that 100% of their components are FEMA/GRAS listed and compliant with the latest toxicology research.

Flavor extracts derived from natural sources (like botanicals) carry the risk of heavy metal contamination (Lead, Arsenic, Mercury) from the soil. Quality manufacturers implement Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to test raw materials at the parts-per-billion level. This level of testing is expensive and is one of the first things “cut” by manufacturers looking to offer the lowest price.

For a consumer brand, consistency is the bedrock of trust. If a consumer opens a bottle of your beverage today and it tastes different from the one they had last week, they won’t blame the flavor supplier—they will blame your brand.

Manufacturing flavors is as much an art as it is a science. Natural extracts vary by season, soil quality, and rainfall. A premium flavor house uses Analytical Standard Matching. We use Gas Chromatography (GC) to ensure that the chemical “fingerprint” of Batch #500 is identical to Batch #1.

Cheap manufacturers often have wider “tolerance bands.” This means that while each batch is “close,” the cumulative drift over a year can result in a product that tastes fundamentally different from its original formulation.

Quality flavor houses employ trained sensory panels—human “super-tasters” who can detect nuances that machines might miss. These panels ensure that the organoleptic properties (taste, smell, mouthfeel, color) meet the “Gold Standard” established during R&D. Without this human oversight, you risk releasing a product that is chemically “correct” but sensorially “off.

Global Flavor Compliance Network

The “cheapest” flavors are usually simple “character” flavors (e.g., just “Orange” or “Vanilla”). However, modern food science often requires functional flavors or modulators.

With the global push for sugar reduction, many brands are moving toward stevia or monk fruit. However, these can have bitter aftertastes or a “thin” mouthfeel. A high-quality flavor house provides modulators that:

The plant-based revolution (pea protein, soy, oat) faces a major hurdle: “beany” or “earthy” off-notes. Cheap flavors simply try to “overpower” these notes with high doses of perfume-like aromatics. Premium masking technology works at a molecular level to neutralize the offending odors, allowing the desired flavor to shine through at lower dosages.

To truly understand why “cheapest isn’t best,” we must look at the Total Cost of Ownership (TCO). Procurement professionals who look only at the Purchase Price are seeing only the tip of the iceberg.

| Cost Element | The “Cheap” Flavor Reality | The Premium Flavor Advantage |

| Direct Purchase Price | Low (e.g., $10/unit) | Moderate (e.g., $18/unit) |

| Dosage Rate | High (Often 2x-3x more) | Ultra-Low / Concentrated |

| Inventory Footprint | Large (requires more warehouse space) | Small (concentrated, takes less space) |

| Freight/Logistics | High (shipping mostly solvents/carriers) | Low (shipping active flavor components) |

| R&D Cycles | Multiple “fixes” needed for stability | “Right First Time” engineering |

| Consumer Retention | Low (due to inconsistency/off-notes) | High (due to superior profile) |

| Recall Risk | Moderate to High | Minimal (Full QC/Traceability) |

In an era of rising shipping costs and ESG (Environmental, Social, and Governance) goals, concentration matters. Shipping one drum of premium flavor that replaces three drums of budget flavor immediately reduces your logistics costs and your carbon footprint.

When a flavor fails a stability test at the six-month mark of a product launch, the cost is astronomical. Your R&D team must drop everything to reformulate, your marketing launch is delayed, and your relationship with retailers is strained. Investing in a quality, stable flavor from the outset is “insurance” against R&D failure.

The modern consumer is increasingly concerned with the “where” and “how” of their food. According to the World Resources Institute, transparency in the supply chain is no longer optional.

While synthetic flavors are safe and efficient, “Natural” flavors must be derived from physical, enzymatic, or microbiological processes. Budget “Natural” flavors sometimes take shortcuts in the extraction process, using harsh solvents that may not align with “Clean Label” philosophies.

Premium manufacturers invest in:

Flavor is the emotional connection between your product and the consumer. It is the memory of a childhood snack, the refreshing “ah” after a cold drink, and the reason a customer reaches for your brand on a crowded supermarket shelf.

Choosing a flavor based solely on price is a gamble where the stakes are your brand’s reputation. By choosing a high-quality, technically superior flavor system, you are investing in:

At our facility, we blend the precision of molecular chemistry with the creativity of world-class flavorists. We invite you to move beyond “commodity” thinking and discover the transformative power of quality flavor.

Joyful Beverage Experience

Are you ready to elevate your product’s sensory profile? Our team of application scientists and flavorists is standing by to help you solve your toughest formulation challenges.

We offer:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.