Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 30, 2026

High-Tech Flavor Analysis Lab

In the hyper-competitive 2026 food and beverage landscape, the “secret sauce” to market dominance isn’t just the flavor itself—it’s the strategic architecture of the partnership behind it. As global supply chains face continued volatility and consumer demands for “Maximalist” and “Intentionally Sensory” profiles peak, manufacturers are shifting from transactional vendor relationships to deep-integrated flavor partnerships.

The role of a flavor house has transitioned from a vendor of essences to a critical node in a brand’s R&D and financial ecosystem. This technical deep dive explores how professional flavor partnerships serve as a dual engine for bottom-line cost reduction and top-line innovation.

For the modern F&B executive, the traditional procurement model—buying flavor as a bulk commodity—is obsolete. A professional flavor manufacturer functions as a secondary engineering arm that manipulates the Cost-in-Use (CiU) rather than just the invoice price.

The most immediate cost-saving lever is the engineering of higher potency systems. Traditional flavors often carry a high percentage of solvents (like Propylene Glycol or Ethanol). A strategic partner works to maximize the “active” aromatic volatiles.

In 2026, climate volatility has made natural “hero” ingredients—such as Madagascar vanilla, Brazilian orange oils, and West African cocoa—highly unstable. A flavor partner utilizes Molecular Deconstruction to identify the key odor-active compounds (KOACs) that define these ingredients.

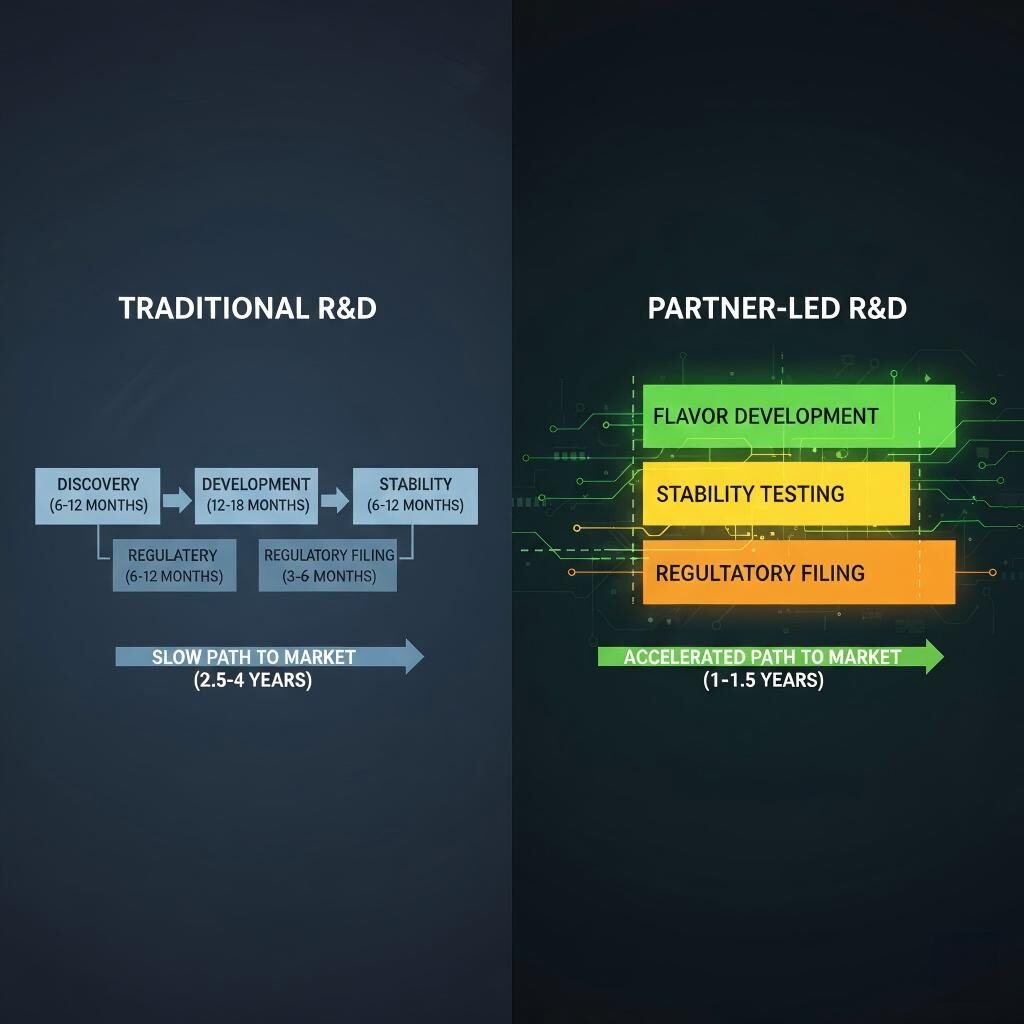

The “Time-to-Market” metric is the lifeblood of 2026’s “Category Crasher” trend. Whether you are launching a savory energy bar or a botanical-infused sparkling water, the speed of iteration determines market share.

Maintaining a full-scale sensory lab and a team of specialized flavorists is a massive overhead. A flavor partnership grants access to:

A common technical failure in F&B innovation is “scalping”—where the packaging or the product matrix (like plant-based proteins) absorbs the flavor. A partner provides Barrier-Resistant Flavor Systems. They adjust the molecular weight and polarity of the flavor molecules to ensure they remain “free” in the product, rather than binding to the plastic lining or the protein isolate.

Accelerated R&D Timeline Comparison

Innovation in 2026 is defined by Maximalism—bold, layered, and multisensory creations. Partnerships allow brands to experiment with high-risk, high-reward profiles that differentiate them from private-label competitors.

The surge in functional beverages (protein milks, mocktails with adaptogens) has introduced bitter and metallic off-notes.

Diagram of Tongue Taste Zones

In the push for “Natural” labels, the partnership now extends to White Biotechnology. Using specific yeast or bacteria strains, flavor houses “grow” natural flavors (like gamma-decalactone for peach or vanillin from ferulic acid). This provides a “Natural” label claim with the consistency and price stability of a synthetic.

According to a recent industry analysis on flavor cost-in-use, strategic formulation can lead to an 18% decrease in total formulation costs while simultaneously improving shelf-life stability (Source: Flavor Cost Analysis: Maximizing Value, 2025).

To truly innovate, a brand must understand how flavor behaves at the molecular level within their specific food matrix. A flavor partnership provides the scientific data to master these interactions.

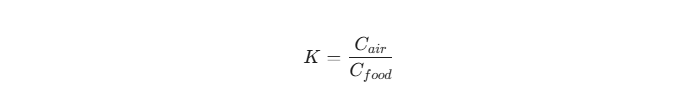

The perception of flavor is not about how much flavor is in the food, but how much flavor is released into the headspace (the air in the mouth and nose). This is governed by the Partition Coefficient:

In a high-fat product, lipophilic flavor molecules (like many fruit esters) tend to stay trapped in the fat phase. A flavor partner will reformulate the flavor using different carriers or “release triggers” to ensure the consumer actually tastes the flavor they’ve paid for. Without this technical adjustment, a significant percentage of the flavor might be swallowed without ever reaching the olfactory receptors.

In 2026, Multi-Stage Flavor Release is a key differentiator.

Consumer transparency is at an all-time high. The Mintel 2026 Global Food and Drink Predictions highlight a move toward “Retro Rejuvenation,” where consumers want traditional ingredients but with modern, clean labels.

A professional flavor manufacturer manages the complex documentation required for international expansion. For instance, the definition of “Natural” varies significantly between the FDA (USA) and the EFSA (EU). A partner ensures that your “Natural Strawberry” label is legally defensible in every market you enter.

A dedicated flavor partner provides the necessary chain-of-custody for:

Upcycled Flavor Essence Process

In 2026, a flavor partnership is a key component of a company’s ESG (Environmental, Social, and Governance) strategy.

Flavor houses are now extracting high-value aroma compounds from food waste streams. For example, capturing the “water phase” volatiles during the concentration of fruit juices, which were previously discarded, and refining them into premium extracts. This reduces agricultural waste and creates a circular economy.

By using ultra-concentrated flavor systems, manufacturers reduce the amount of water and solvent shipped across the globe. This significantly lowers the Scope 3 emissions associated with a brand’s supply chain and reduces packaging waste (fewer drums/IBCs required).

A major manufacturer of oat milk faced a challenge: the product lacked the “richness” of dairy and had a distinct “earthy/cereal” aftertaste.

Professional manufacturers use enzymes to generate flavor in situ.

For savory and bakery applications, we provide “Reaction Flavors.” These are created by heating amino acids with reducing sugars under controlled pH and pressure. This mimics the “crust” of a bread or the “sear” of a steak, allowing manufacturers to achieve “oven-roasted” profiles in microwaveable or cold-fill products.

As brands move toward “Fresh” and “Cold-Pressed” claims, they use HPP instead of heat. However, HPP can change the structure of flavor molecules. Our R&D team tests every flavor for “HPP Stability,” ensuring that the strawberry flavor doesn’t turn “jammy” or “metallic” under 600 MPa of pressure.

The final frontier of flavor partnerships is Predictive Consumer Science. Using AI and social media scraping, flavor partners can predict which “Flavor of the Year” will dominate 18 months before it hits the mainstream.

Whether it is the 2026 obsession with “Spicy-Floral” (like Chili-Hibiscus) or “Earth-Sweet” (like Miso-Caramel), a partner allows a brand to be first-to-market with a stable, production-ready formula.

In an era of labor shortages and rising operational costs, the most successful food and beverage companies are those that stop viewing flavor as a raw material and start viewing it as a technological asset. A robust partnership reduces the “trial-and-error” phase of development, slashes commodity expenses, and ensures that every launch is backed by rigorous sensory science.

As a professional manufacturer of food and beverage flavors, we specialize in helping brands navigate the intersection of taste and economics. Our 2026 Flavor Portfolio is designed to meet the demands of a new generation of consumers while protecting your margins.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Future Crafted Together

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.