Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 24, 2026

Bulk vs. Custom Flavor Production

In the rapidly evolving landscape of food and beverage manufacturing, the “flavor profile” is the most critical differentiator for brand success. Whether you are a multinational beverage corporation or a burgeoning craft snack producer, the decision between utilizing Bulk (Standard) Flavors or Custom (Bespoke) Flavors is a pivot point that impacts your R&D budget, supply chain agility, and consumer loyalty.

As professional manufacturers of food and beverage flavorings, we understand that this is not a binary choice. It is a strategic balancing act. This technical guide explores the nuances of flavor procurement, the chemistry of customization, and how to optimize your production needs for maximum ROI.

Before diving into the strategic application, we must establish a clear technical baseline for these two procurement models. The flavor industry operates on a spectrum of complexity, ranging from basic aroma chemicals to highly engineered multi-component systems.

Bulk flavors, often referred to as “catalog flavors,” are pre-formulated, high-volume profiles that have been stabilized and standardized for the general market. These are the “Vanilla Type 101” or “Natural Lemon” profiles that serve as the backbone of the industry.

Custom flavors are engineered for a specific application, a specific matrix (e.g., high-protein, low-sugar), or a specific brand identity. These are not merely “tweaks” to existing formulas; they are ground-up formulations designed to solve a technical challenge or meet a unique sensory target.

Bulk flavors are the workhorses of the food industry. According to the Flavor and Extract Manufacturers Association (FEMA), the use of standardized GRAS flavoring substances allows for a streamlined manufacturing process that maintains safety and consistency at scale. (Citation 1).

In a world of fluctuating raw material costs, bulk flavors offer a “safety net.” Because manufacturers produce these in large quantities, they often hold significant safety stock, protecting you from sudden shortages of specific aromatic chemicals. For commodity products, this reliability is often more valuable than a unique sensory profile.

Bulk flavors are ideal for:

Why do manufacturers choose to pay a premium for custom flavors? The answer lies in the interaction between flavor molecules and the food matrix. Modern food science has moved beyond simple “taste adding” to “taste engineering.”

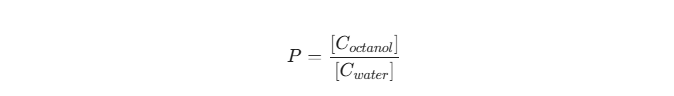

In many modern packaging systems, flavor molecules can be absorbed by the plastic liner or migrate through the product itself—a phenomenon known as flavor scalping. A custom flavor is engineered with specific Partition Coefficients (P) to ensure the flavor stays in the product and not in the packaging.

By adjusting the hydrophobicity of the flavor carrier, we can ensure maximum “flavor impact” even after six months on the shelf. For example, if your packaging is a polyolefin-based film, we avoid non-polar terpenes that would be easily absorbed by the plastic.

The rise of functional foods—high-protein shakes, keto-friendly snacks, and vitamin-fortified waters—has introduced aggressive off-notes. Bulk flavors often lack the specific “blockers” needed to neutralize these.

The decision-making process is often dictated by your project’s timeline and the depth of your technical resources.

| Feature | Bulk Flavors | Custom Flavors |

| Development Time | 0 – 2 Weeks (Sampling) | 4 – 12 Weeks (Formulation) |

| Minimum Order Quantity (MOQ) | Low (often 10-25 kg) | High (often 100-500 kg) |

| Technical Support | Documentation only | Bench-top application & Pilot trials |

| Sensory Complexity | Linear / Simple | Multi-layered / Complex |

| Unique Selling Point | Cost & Speed | Brand Identity & Differentiation |

According to a report by Grand View Research, the global flavor and fragrance market is seeing a massive shift toward “natural” and “clean-label” customization. As consumers move away from generic synthetic profiles, the value of bespoke formulations has increased, particularly in the Asia-Pacific region. (Citation 2).

The most successful manufacturers do not choose one over the other in a vacuum. They use a Hybrid Flavor Strategy to optimize both their balance sheet and their sensory profile.

In this model, a manufacturer uses a Bulk Flavor for 80% of the profile (the “Body”) to provide foundational sweetness and mouthfeel. They then apply a Custom Flavor at 20% (the “Signature”) to provide the unique aromatic “bloom.”

Sometimes, a bulk flavor is selected for its taste, but a custom Flavor Carrier System (like a specific oil-in-water emulsion) is designed to make that bulk flavor survive a specific industrial process, such as retorting, UHT (Ultra-High Temperature) pasteurization, or deep-freezing.

The regulatory burden differs significantly between these two paths. When you choose a flavor, you are also choosing a legal framework for your label.

For Bulk Flavors, the Safety Data Sheets (SDS) and Technical Data Sheets (TDS) are instantaneous. For Custom Flavors, these must be generated after the formulation is finalized. If you are aiming for an “Organic” or “Non-GMO Project Verified” label, custom formulations are often the only way to ensure every sub-component of the flavor—including the solvents and carriers—meets the strict requirements.

The U.S. Food and Drug Administration (FDA) requires precise labeling for “Natural” vs. “Artificial” flavors under 21 CFR 101.22. Customizing your flavor allows you to choose specific natural precursors that satisfy both regulatory requirements and consumer expectations for “Clean Label” transparency. (Citation 3).

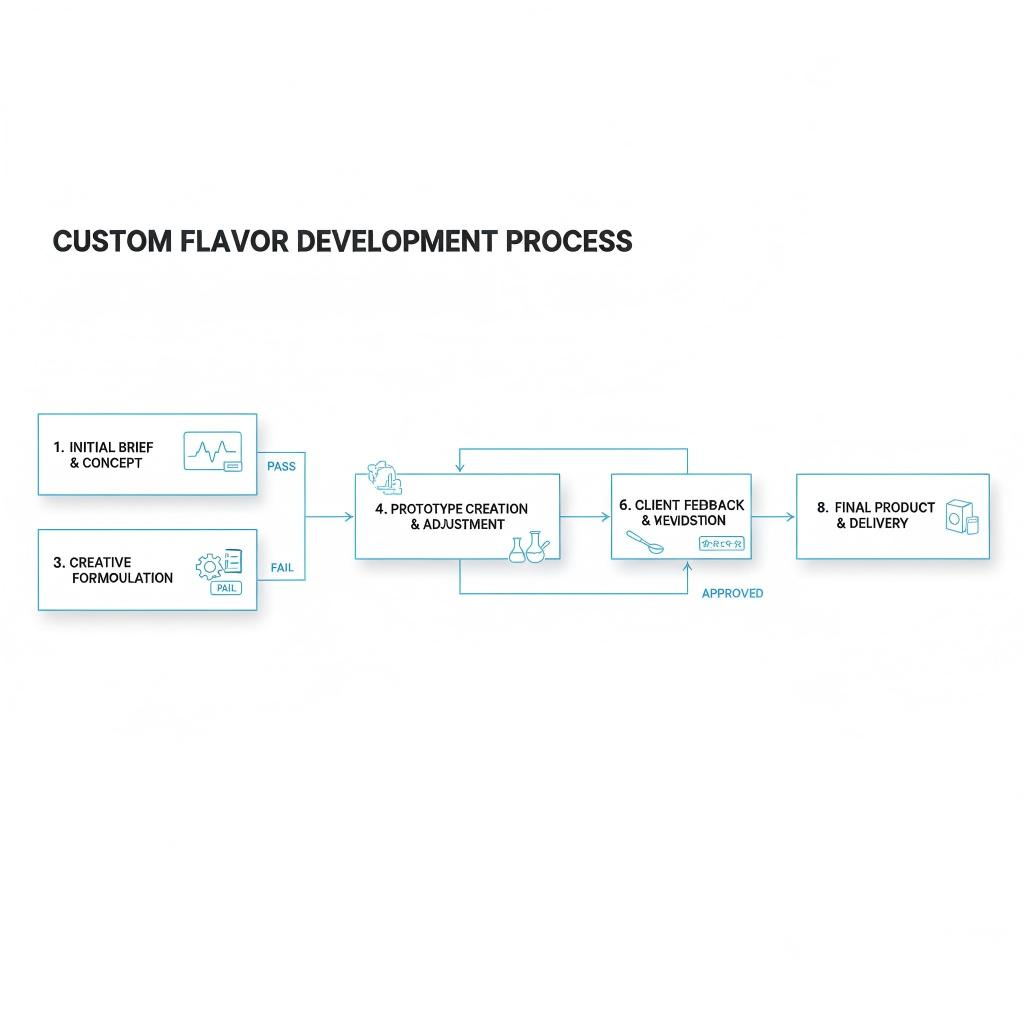

Flavor Development Flowchart

To truly find the right balance, one must understand how flavors are released in the mouth. This is the difference between a product that tastes “okay” and one that tastes “premium.”

Customization allows for the use of advanced encapsulation technologies like Spray-Drying or Micro-encapsulation. This protects the flavor from oxygen and light, ensuring that a snack produced in January tastes just as fresh when it is opened in July.

How do you decide for your next production run? Use this decision matrix to guide your team:

According to industry insights from Mordor Intelligence, the “LTO” market thrives on bulk flavors because the rapid turnover does not justify the R&D investment of a custom build, whereas permanent flagship products almost always transition to custom formulas. (Citation 4).

When evaluating flavors, looking at the “Price per Kilogram” is the most common mistake in procurement. Instead, you must look at the Usage Level (Dose Rate) and the Impact on Final Yield.

A Bulk Flavor may cost 20/kg but require a 0.2% dose to be perceptible. A Custom Flavor may cost 40/kg but only require a 0.05% dose due to its higher concentration of “impact chemicals.”

Custom flavors are designed to be stable. If a bulk flavor degrades during production, you may have to discard a 5,000-gallon batch of product. The “insurance” provided by a custom-stabilized flavor often pays for itself in the reduction of industrial waste alone.

GC-MS Flavor Analysis Screen

As we look toward the future, the “Bulk vs. Custom” debate is being transformed by Artificial Intelligence.

We now use AI algorithms to analyze thousands of consumer sensory reviews and predict which flavor molecules will be most successful for a specific demographic. This allows us to create “Custom-Lite” flavors—profiles that are more effective than bulk catalog items but developed faster than traditional custom builds.

As the market moves toward personalized nutrition, flavors will need to be customized not just for brands, but for specific biological needs (e.g., low-sodium flavors that still trigger the brain’s “salty” reward center). Custom flavor manufacturers are at the forefront of this medical-grade food revolution.

Even with the best flavor, production issues can occur. Here is how to identify whether your flavor choice is the culprit:

11.1 Problem: “Flavor Fade” (Taste disappears after 2 months).

11.2 Problem: “Off-Notes” (Product tastes like cardboard or grass).

11.3 Problem: “Inconsistent Batches.”

The choice between bulk and custom flavors is not just a procurement decision; it is a fundamental part of your product’s engineering. By understanding the chemical interactions, the R&D timelines, and the true cost-in-use, you can find the balance that drives both profitability and consumer delight.

At our manufacturing facility, we specialize in both. We maintain an extensive library of high-performance bulk flavors for rapid deployment and a world-class R&D lab dedicated to crafting the bespoke profiles that define tomorrow’s market leaders. Whether you need the speed of a catalog lemon or the complexity of a signature botanical blend, our technical team is here to ensure your “first bite” is perfect.

Flavor Science Partnership

Are you struggling to choose the right flavor path for your next project? Let’s turn chemistry into a competitive advantage.

Would you like to schedule a technical exchange with our lead flavorists to audit your current formulations, or would you like to request a free sample kit of our top-performing bulk flavors for a bench-top trial?

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.