Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Feb 07, 2026

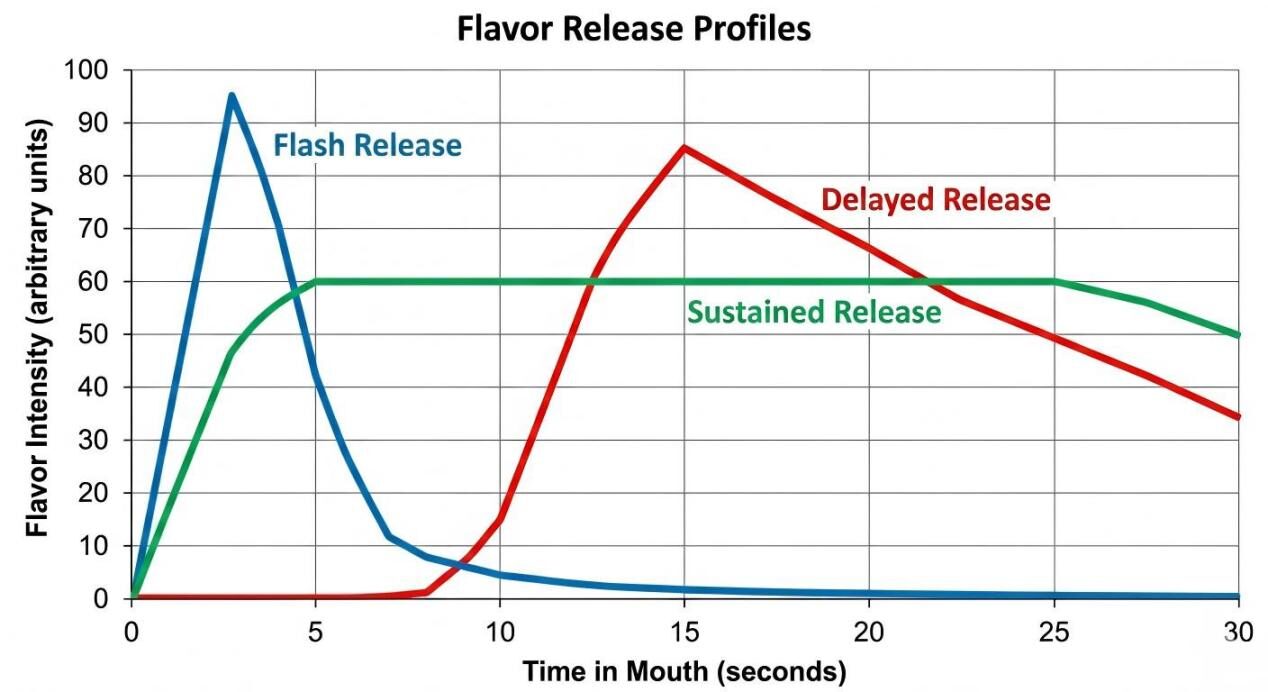

Flavor Release Profiles Graph

In the high-stakes world of professional food and beverage manufacturing, flavor is rarely viewed as a static ingredient. Instead, it is understood as a dynamic, temporal event. When a consumer interacts with a product, they are participating in a complex “sensory arc” that begins the moment the package is opened and continues long after the final swallow.

The fundamental challenge for the modern flavor chemist is not just the creation of a balanced aromatic profile, but the mastery of flavor release kinetics. This is the science of controlling exactly when and how volatile and non-volatile compounds transition from the food matrix into the sensory receptors of the consumer. A flavor that releases too early during processing is lost to the environment; a flavor that releases too slowly in the mouth is perceived as muted or “flat.”

As a leading manufacturer of advanced flavoring solutions, we recognize that “performance” is defined by precision. This article provides an authoritative technical exploration of the mechanisms governing flavor delivery, the role of the food matrix, and the sophisticated triggers used to engineer the perfect consumer experience.

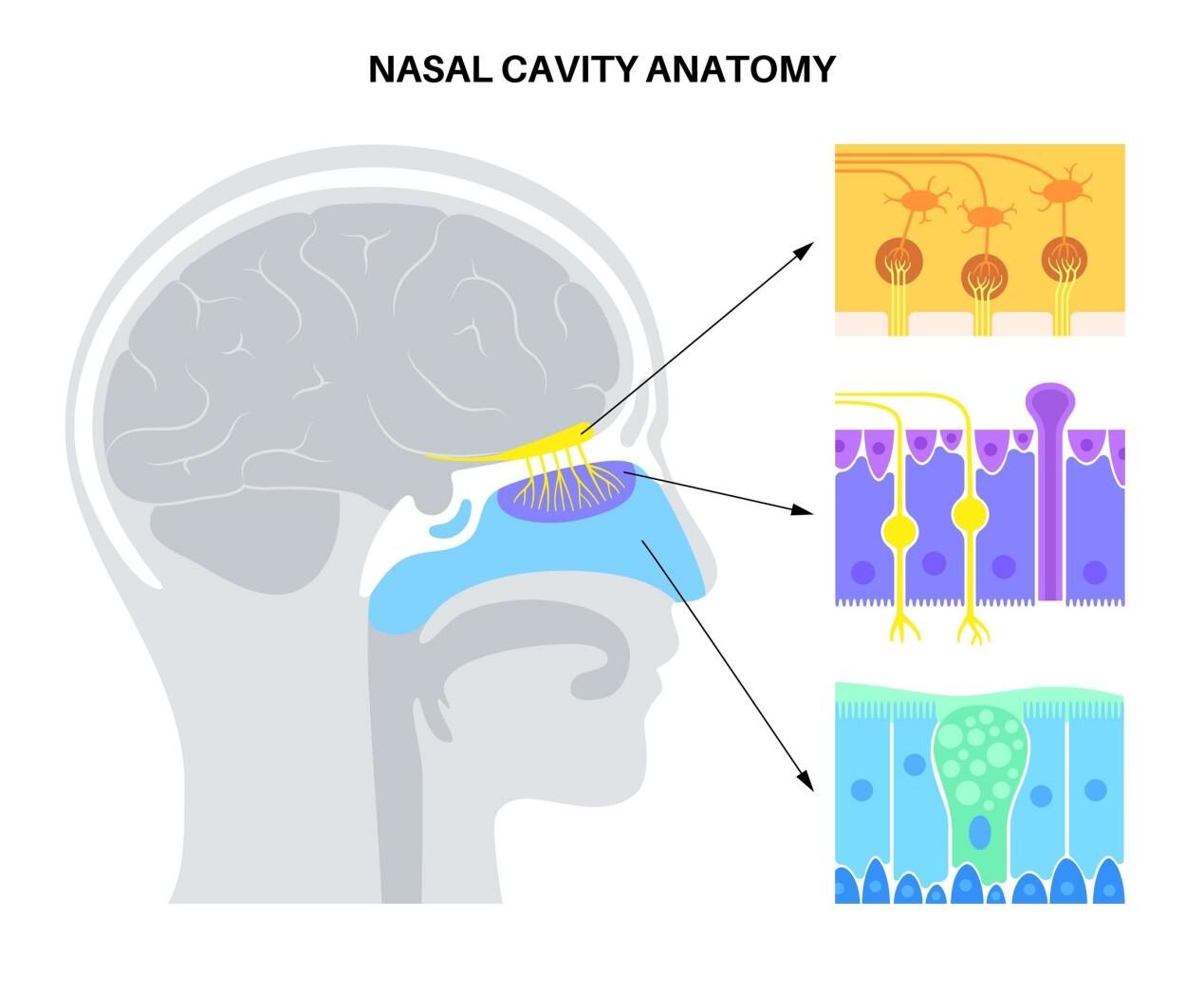

To engineer effective release mechanisms, we must first map the biological path that flavor molecules take. The human perception of flavor is a multi-modal synthesis involving taste (tongue), aroma (olfactory system), and chemesthesis (trigeminal nerve sensations like heat or cooling).

Aroma compounds are the primary drivers of flavor diversity. These volatile molecules reach the olfactory epithelium via two distinct routes:

Nasal Cavity Anatomy Diagram

The physical act of eating is a destructive process. Teeth provide mechanical shear, while the tongue provides compression. Crucially, the introduction of saliva (an aqueous, enzymatic fluid) initiates both chemical dissolution and enzymatic breakdown. Professional flavor design must account for the “dilution factor” of saliva and its pH-buffering capacity, which can alter the solubility of flavor carriers.

Citation 1: Research published by Wageningen University & Research highlights that the “bolus formation”—the mass of chewed food mixed with saliva—is the critical phase where flavor partitioning between the food matrix and the headspace is decided.

At the heart of flavor release is the concept of Equilibrium Partitioning. This is mathematically expressed as the Partition Coefficient (Kaw), which represents the ratio of a flavor compound’s concentration in the air (Cair) versus its concentration in the product/water (Cproduct).

Each aroma chemical has a specific vapor pressure. High-vapor-pressure molecules (like top-note esters) want to escape the food matrix rapidly. Lower-vapor-pressure molecules (like vanillin or heavy lactones) prefer to stay in the liquid or solid phase.

In a professional flavoring system, we manipulate Kaw by adjusting the chemical environment. For example, adding salts can “salt out” flavor molecules, pushing them into the air phase and increasing perceived intensity. Conversely, using “fixatives” or specific polymers can lower the Kaw , holding the flavor in the product for a longer duration.

For liquid beverages, Henry’s Law is the guiding principle. It describes how gas (aroma) dissolves in liquid based on pressure. When a carbonated beverage is opened, the release of CO2 bubbles acts as a “carrier gas,” stripping flavor volatiles from the liquid and delivering them in a concentrated burst to the nose—a phenomenon known as “bubble-mediated flavor release.”

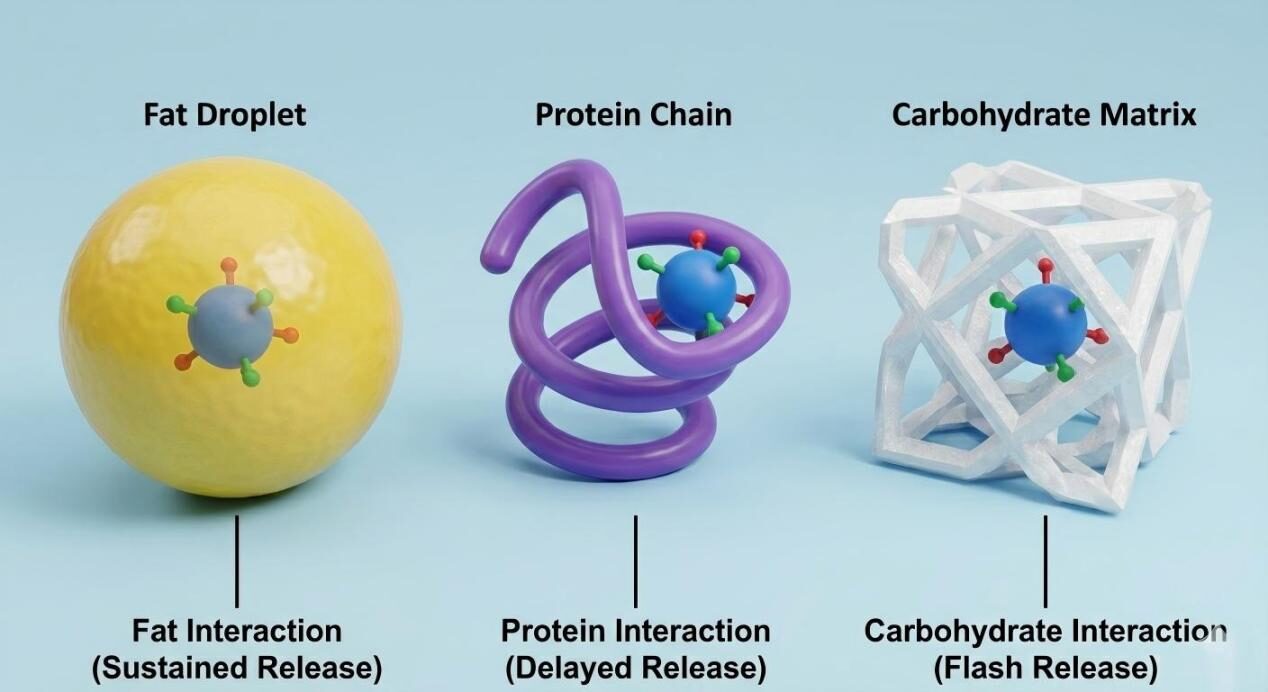

The food matrix (the proteins, lipids, and carbohydrates that make up the product) is not an inert carrier; it is a complex chemical reservoir that interacts with flavor molecules through various bonding mechanisms.

Most aromatic compounds are lipophilic (fat-soluble). Consequently, the fat content of a food product is the single most significant factor in flavor release.

Proteins can bind flavor molecules through hydrophobic interactions or covalent bonding. This is particularly problematic in the growing plant-based protein sector (pea, soy, oat).

In dry snacks and powders, carbohydrates like maltodextrin or sucrose are used as the matrix. The key here is the Glass Transition Temperature (Tg).

Understanding the Tg of your specific product is essential for ensuring that flavor release happens in the mouth, not in the warehouse.

Flavor Matrix Interaction Infographic

The hallmark of a professional-grade flavor is the use of Release Triggers. We do not want the flavor to release randomly; we want it to release in response to a specific environmental change.

This is the most common mechanism for instant beverages, drink sticks, and dry mixes.

Essential for the bakery and frozen food industries.

Crucial for chewing gum, confectionery, and “burst-bead” snacks.

Often used in functional beverages or products containing sensitive active ingredients (like vitamins or minerals).

Citation 2: According to the Institute of Food Technologists (IFT), the development of “stimuli-responsive” encapsulation systems is the frontier of flavor science, allowing for precision nutrition and enhanced consumer delight.

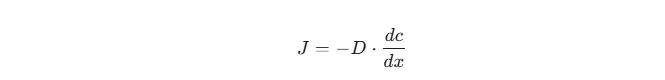

For our R&D partners, we move beyond qualitative descriptions and into quantitative modeling. We analyze flavor release through the lens of Fick’s Laws of Diffusion.

The rate of flavor release (J) is proportional to the concentration gradient (dc/dx):

Where D is the diffusion coefficient. In a controlled-release system, we manipulate D by:

By fine-tuning these mathematical variables, we can ensure that a “Citrus” top note and a “Vanilla” base note—which have naturally different release speeds—appear to the consumer to be perfectly synchronized.

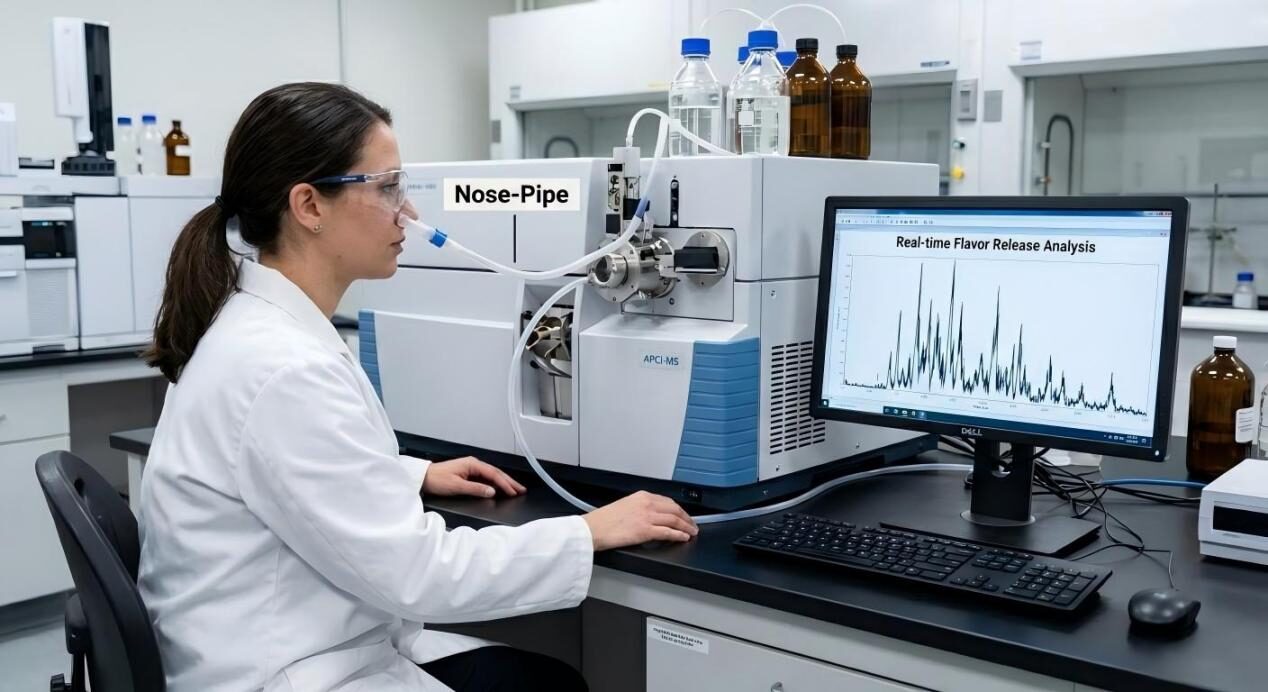

How do we know the flavor is releasing correctly? We use “In-Vivo” (real-time) analytical techniques that bypass human subjectivity.

This is the gold standard for flavor release analysis. We connect a mass spectrometer directly to the nose of a human subject via a “nose-tracker.”

For high-throughput screening, we utilize “E-noses” equipped with gas sensors that mimic the human olfactory response. This allows us to test hundreds of encapsulation iterations in a single day to find the one with the most efficient release profile.

Citation 3: The American Chemical Society (ACS) publishes extensive research on the use of “MS-Nose” technology to bridge the gap between instrumental data and sensory panel scores.

Real-Time Aroma Analysis

A perfect release mechanism designed in a lab must survive the “Industrial Gauntlet.” High-speed mixing, extrusion, and UHT (Ultra-High Temperature) processing can destroy delicate capsules.

In high-shear mixers, capsules can be physically crushed. We offer “Reinforced Shell” technology—encapsulates specifically designed with high compressive strength to survive the mechanical stress of industrial food production without leaking.

In liquid applications, “Flavor Creep” can occur. This is when the flavor slowly migrates from the capsule into the liquid base during storage. We prevent this by optimizing the Hydrophilic-Lipophilic Balance (HLB) of the emulsifiers used in the encapsulation process.

It is a little-known fact that plastic packaging can “suck” flavor out of a food product. This is known as Scalping. Many polymers used in bottles or pouches have a high affinity for certain flavor esters. Our encapsulated solutions act as a barrier, not just against oxygen, but against the packaging itself, ensuring the flavor stays in the food, not the plastic.

As the industry moves toward “Clean Label” and sustainable sourcing, the materials we use to control flavor release are evolving.

Citation 4: The U.S. Food and Drug Administration (FDA) and EFSA continue to update the “Generally Recognized as Safe” (GRAS) lists for novel carrier materials, ensuring that innovation in flavor release never compromises consumer safety.

The difference between a “good” product and a “legendary” one often comes down to a matter of seconds. It is the difference between a flavor that arrives precisely when the consumer expects it and one that is lost in the noise of the food matrix.

Controlling flavor release is an interdisciplinary challenge. It requires a deep understanding of human physiology, the thermodynamics of partitioning, the material science of the food matrix, and the precision of mechanical engineering.

As your professional flavor manufacturing partner, our goal is to give you total control over the sensory timeline of your product. We don’t just provide “taste”; we provide a sophisticated delivery architecture that protects your brand’s signature profile and ensures that every bite or sip is as impactful as the first.

Premium Sensory Hero Shot

Is your flavor profile underperforming? Are you struggling with “flavor fade” or high-heat processing losses? Let’s turn your sensory challenges into a competitive advantage.

Our technical team is ready to assist you with:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.